Sample Pages Preview

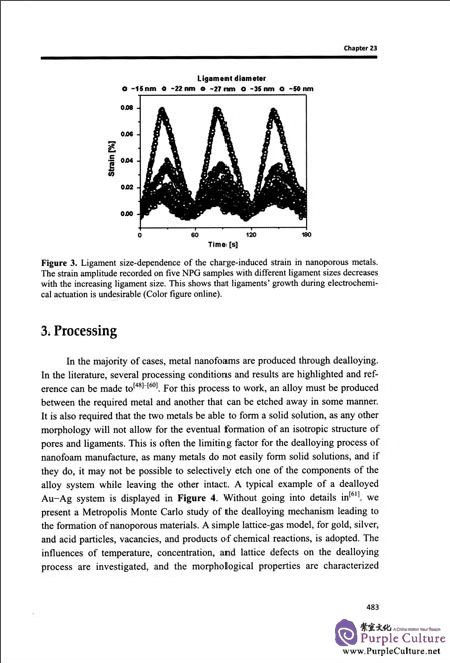

In this contribution, we will review some aspects of this fast growing field and highlight a couple ofideas of applications in the outlook section that may also have a great impact onto the field of energy—related materials.While the production of nanoporous etallic structures is well—documented, up until recently very little was known about their mechanical properties—at submicron scales, sample size has the possibility to produce a large effect on mechanical properties, where in macroporous foams cell size specifically does not have an influence on material strength.Indeed, it is highly uncertain that the behaviors of macroscopic and microscopic foams will be at all similar in principle and nature.Li and Sieradzki reported that porous Au undergoes a ductile—brittle transition that seemed to be influenced by the microstructural length scale of the material.Biener et al.have continued this investigation into the mechanical properties of nanoporous Au through nanoindentation.They reported the main deformation mechanism during nanoindentation as a ductile, plastic densification.Strong long—range stress fields, brittle fracture, and crack emission were not observed.They note that the scaling laws that are typically applied to macroporous foams apply poorly to nanoporous metals, as they observe experimental yield strength of 145MPa instead of the expected 16MPa.